In the realm of electronic engineering, the pursuit of miniaturization represents a constant challenge and opportunity. At ISI, we’ve honed our expertise in miniaturizing circuitry and producing highly capable electronic modules that defy traditional size constraints. In this blog post, we’ll identify and address the five most important design and manufacturing considerations that underpin our success:

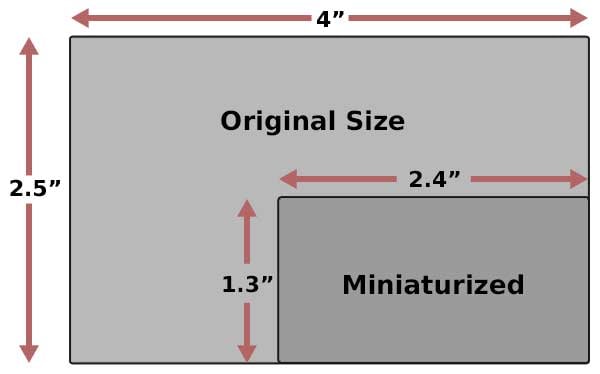

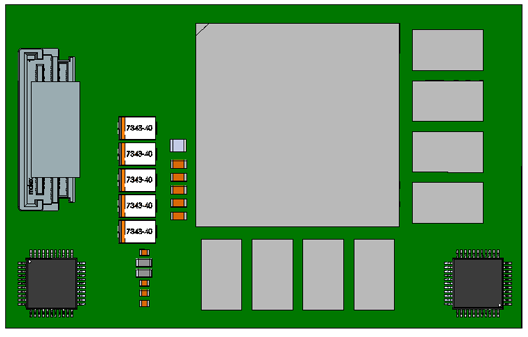

Original Module

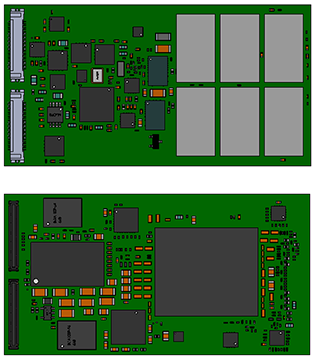

Miniaturized

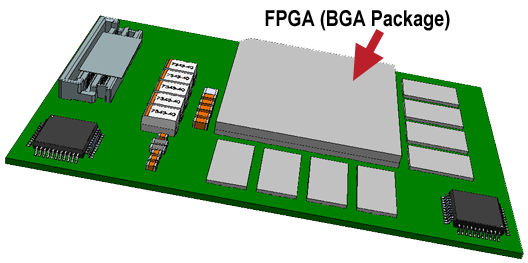

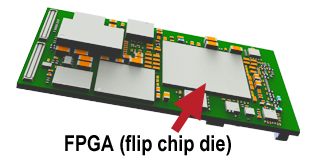

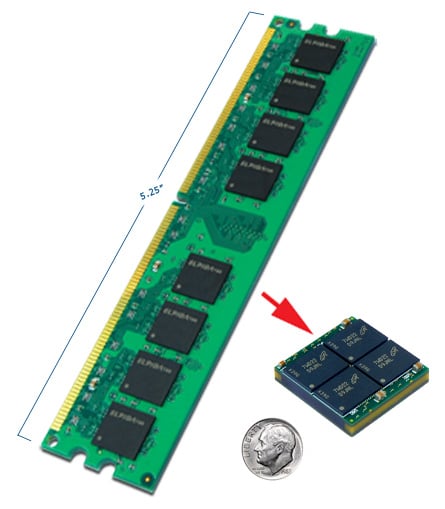

- Component Selection and Integration: Miniaturization isn’t simply about reducing the size of individual components; it’s about optimizing the integration of these components within the module. Selecting the right components with compact footprints and low power consumption is essential. Additionally, careful consideration must be given to the layout and placement of these components to maximize efficiency and minimize interference.

- Thermal Management: As electronic devices become smaller and more densely packed, heat dissipation becomes a critical concern. Effective thermal management is essential to prevent overheating and ensure long-term reliability. This involves designing efficient heat sinks, incorporating thermal vias, and selecting materials with high thermal conductivity. Simulation and testing play a crucial role in verifying the effectiveness of thermal management solutions.

- Manufacturability and Yield Optimization: Miniaturization introduces unique challenges in manufacturing, including smaller tolerances, increased complexity, and reduced accessibility for assembly and testing. Designing for manufacturability is paramount, requiring close collaboration between design engineers and manufacturing specialists. Techniques such as Design for Assembly (DFA) and Design for Testability (DFT) are instrumental in streamlining the production process and maximizing yield.

- Reliability and Environmental Considerations: Smaller electronic modules are often deployed in demanding environments where they may be subjected to temperature extremes, mechanical shock, vibration, and moisture. Ensuring robustness and reliability under such conditions requires comprehensive testing and adherence to stringent quality standards. This includes selecting durable materials, implementing protective coatings, and conducting accelerated life testing to assess long-term performance and reliability.

- Signal Integrity and EMI/RFI Mitigation: Shrinking circuitry can exacerbate issues related to signal integrity and electromagnetic interference (EMI) or radio-frequency interference (RFI). Careful attention must be paid to signal routing, impedance matching, and shielding techniques to maintain signal integrity and minimize electromagnetic emissions. Advanced simulation tools and rigorous testing protocols are indispensable for identifying and addressing potential interference issues early in the design phase.

By addressing these five critical considerations—component selection and integration, thermal management, manufacturability and yield optimization, signal integrity and EMI/RFI mitigation, and reliability and environmental considerations—we’re able to deliver miniaturized electronic modules that not only meet but exceed the expectations of our customers.

Our Approach

Our approach to miniaturization is meticulous and strategic. We leverage advanced technologies like surface mount technology (SMT) and high-density interconnect (HDI) PCB designs to increase component density and optimize space utilization. Our PCB designers collaborate closely with clients to ensure that each design meets stringent requirements while maintaining signal integrity and effective thermal management.

The Miniaturization Challenge

In this example (pictured below), we show the typical results of what ISI can achieve when our customers approach us with a challenge to miniaturize an existing design. Imagine taking a robust electronic module, measuring 4 inches by 2.5 inches, and reducing its size to a mere 2.4 inches by 1.3 inches. This isn’t simply a size reduction; it’s a complete re-engineering of the device to enhance its functionality while occupying nearly 70% less space.

Before & After Miniaturization

Driving Innovation Across Industries

The benefits of miniaturized electronic modules are vast. They offer unparalleled space optimization, enabling the integration of multiple functionalities into compact devices. This is particularly crucial for sectors like defense and aerospace, where size and weight are critical constraints.

By minimizing signal propagation distances, we also achieve faster data processing and improved energy efficiency, which are invaluable in applications requiring real-time decision-making, such as avionics systems and unmanned aerial vehicles (UAVs).

FAQ's

Partnering for Success

At ISI, we don’t just create products; we forge partnerships. Our dedicated team of engineers works hand-in-hand with customers to tailor solutions that balance size, performance, and functionality. We’re not just a service provider; we’re a partner in innovation.

Download PDF

Download a summary of this case study in PDF format.

Enter your email for access